Hello everyone I dont normally post all that much but I think this will make a great thread! About 3 years ago my Dad and I found a Cole Superhawk in California on craigslist. We called the guy and talked to him and he said it was in good condition and just needed a little TLC and some clean up and would be good to go as well it had always been stored indoors. Well we are from Colorado so we decided well it looks good for the price which was 9,500 as I remember so we decided lets go check it out and we jumped on a plane to go check it out. Also we needed another boat for our annual Lake Powell vacation due to the amount of people we always have. So we show up and look at it and the guy had obviously lied to us the boat was very dirty and cooked by the sun so we thought about it some and decided we are in a time crunch for another boat at Powell so we offered him 8,000 and he took it. We got the boat going for the summer and at the end decided to rebuild it and started to take it apart. So here is the rebuild pictures of it as we went along. My Dad and I did all the work except for the gel coat, paint and powder coat and My Mom and younger brother did all the upholstery work except for the embroidery done on the seats. So here is the true family rebuild of a Cole Superhawk.

So here is the pictures of the boat the day after we got it home from California. As rough as it looks we got it running the night before we went to Lake Powell for a week over July 4th and we went with this boat and my Dads 27.5 Stingray ( i will post a picture since it is pretty cool as well) but the boat ran great at the lake but we did have a mechanical fuel pump go out and Bullfrog marina had one so we were back in business before we knew it! We noticed that the boat felt good but it for sure wasn't a super sound boat so we decided to start the tear down to see what we had going for us and it wasn't pretty might be a nice way to put it. Here is the pictures of the start of it.

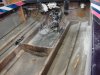

We were hoping that only part of the floor was rotten and we could spot it and still have a good floor but the more we cut out the worse it started to look and pretty soon we had the carpet, seats, seat bases, hardware, engine, windshields, floor, one stringer and whatever else we could think of out of the boat.

So here is the pictures of the boat the day after we got it home from California. As rough as it looks we got it running the night before we went to Lake Powell for a week over July 4th and we went with this boat and my Dads 27.5 Stingray ( i will post a picture since it is pretty cool as well) but the boat ran great at the lake but we did have a mechanical fuel pump go out and Bullfrog marina had one so we were back in business before we knew it! We noticed that the boat felt good but it for sure wasn't a super sound boat so we decided to start the tear down to see what we had going for us and it wasn't pretty might be a nice way to put it. Here is the pictures of the start of it.

We were hoping that only part of the floor was rotten and we could spot it and still have a good floor but the more we cut out the worse it started to look and pretty soon we had the carpet, seats, seat bases, hardware, engine, windshields, floor, one stringer and whatever else we could think of out of the boat.