Toolman

Well-Known Member

- Joined

- Aug 19, 2014

- Messages

- 416

- Reaction score

- 554

We got hired to design and produce a socket wrench for a plastic PVC threaded cap. The cap gets torqued to 30 foot pounds. Customer currently uses a rubber strap wrench to tighten the cap. The cap measures approximately 7 inches on the diameter.

Customer supplied his own material which was cut 1/4 of an inch over finished length and 1/2 an inch over the finished diameter. I machined the front and rear faces on the engine lathe parallel and to finished length. Because I don’t have enough material to grab onto when turning the outer diameter, I moved it to the CNC lathe and friction drove it to finished diameter not hitting it too hard causing it to slip. Now I am able to grab it from the outside and rough bore the inside of the socket.

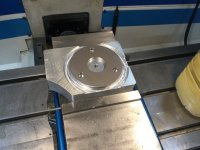

Now I move it to my TRM ( tool room mill) and cut the 12 slots that mate up to the fins on the cap and the 3 threaded holes for the driver plate.

On the driver plate I popped the three holes in the customer supplied blanks. Then I make a quick little fixture and I bolt the blanks to the fixture through the holes and mill the OD and the ID of the blanks.

I went and bought a 1 inch diameter by half inch drive black oxide impact socket and welded it to the driver plate.

Customer supplied his own material which was cut 1/4 of an inch over finished length and 1/2 an inch over the finished diameter. I machined the front and rear faces on the engine lathe parallel and to finished length. Because I don’t have enough material to grab onto when turning the outer diameter, I moved it to the CNC lathe and friction drove it to finished diameter not hitting it too hard causing it to slip. Now I am able to grab it from the outside and rough bore the inside of the socket.

Now I move it to my TRM ( tool room mill) and cut the 12 slots that mate up to the fins on the cap and the 3 threaded holes for the driver plate.

On the driver plate I popped the three holes in the customer supplied blanks. Then I make a quick little fixture and I bolt the blanks to the fixture through the holes and mill the OD and the ID of the blanks.

I went and bought a 1 inch diameter by half inch drive black oxide impact socket and welded it to the driver plate.

Attachments

-

A4592E90-6001-44A0-9DC0-8EA644B03B6F.jpeg912.1 KB · Views: 105

A4592E90-6001-44A0-9DC0-8EA644B03B6F.jpeg912.1 KB · Views: 105 -

0395C784-BACB-49C6-A742-1F91AA121666.jpeg789.6 KB · Views: 98

0395C784-BACB-49C6-A742-1F91AA121666.jpeg789.6 KB · Views: 98 -

IMG_4427.MOV60.2 MB

-

2FB56E93-B059-4FAD-A418-12DE215E756B.jpeg947 KB · Views: 91

2FB56E93-B059-4FAD-A418-12DE215E756B.jpeg947 KB · Views: 91 -

6058EC23-5878-44C8-A973-EB4EB47854BD.jpeg842.5 KB · Views: 93

6058EC23-5878-44C8-A973-EB4EB47854BD.jpeg842.5 KB · Views: 93 -

F2B21D56-8158-451A-B98B-EBCD1FA8D045.jpeg967.6 KB · Views: 93

F2B21D56-8158-451A-B98B-EBCD1FA8D045.jpeg967.6 KB · Views: 93 -

89D52DDF-FF9E-412C-BA0A-B5A237E6D871.jpeg940.6 KB · Views: 92

89D52DDF-FF9E-412C-BA0A-B5A237E6D871.jpeg940.6 KB · Views: 92 -

12C7FE4B-455D-43F1-9739-2020D0BE22FC.jpeg1.3 MB · Views: 93

12C7FE4B-455D-43F1-9739-2020D0BE22FC.jpeg1.3 MB · Views: 93 -

8097873D-67DD-428A-95DB-A83F2F6A6E16.jpeg915.4 KB · Views: 95

8097873D-67DD-428A-95DB-A83F2F6A6E16.jpeg915.4 KB · Views: 95 -

14FE1510-4DD9-462D-B880-D355B182B3E9.jpeg1 MB · Views: 100

14FE1510-4DD9-462D-B880-D355B182B3E9.jpeg1 MB · Views: 100 -

83DB0E8B-9C9F-4D45-B73D-44EA96D0D7AE.jpeg1 MB · Views: 112

83DB0E8B-9C9F-4D45-B73D-44EA96D0D7AE.jpeg1 MB · Views: 112 -

5C2C8791-BB71-4CA0-A5F7-C212F7A3B385.jpeg960.2 KB · Views: 108

5C2C8791-BB71-4CA0-A5F7-C212F7A3B385.jpeg960.2 KB · Views: 108

Last edited: