Guest

Director...

- Joined

- Sep 13, 2007

- Messages

- 27,539

- Reaction score

- 3,323

This is an in progress....(slow progress)...resto on my Cobra.....currently #2 in line behind a boat in fixing up....

********************************************************

So I wind up with this Cobra....Nice Car...lots of power....red all over......It needs some changes..

Car Specs...

Fiberglass body on full tube frame....Fuel cell and battery in trunk...Mustang 2 front end with tubular cross bar....very nice chassis....4 link Alston Rear ...coil overs and disc brakes on all 4 corners....466 full roller Ford.. C6 trans.. and a 410 Detroit locker rear end....Definately a stout package... The car is tight and launches VERY hard....No heater no stereo no wipers ....just fast...

What will change....

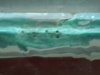

I like my Cobras to be blue.....So I will be smoothing the body,and taking care of a few spider cracks before painting it sunset blue pearl with a white stripe...

The car came with a hideous Pinto/Mustang 2 shifter that has to go...I bought a Hurst Quarter stick shifter for it ....

The engine compt will be detailed .......The chassis will be detailed and painted as well...

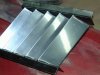

The Sidepipes and headers are hot coated

I will be posting the progress...

Here are the before Pics...

********************************************************

So I wind up with this Cobra....Nice Car...lots of power....red all over......It needs some changes..

Car Specs...

Fiberglass body on full tube frame....Fuel cell and battery in trunk...Mustang 2 front end with tubular cross bar....very nice chassis....4 link Alston Rear ...coil overs and disc brakes on all 4 corners....466 full roller Ford.. C6 trans.. and a 410 Detroit locker rear end....Definately a stout package... The car is tight and launches VERY hard....No heater no stereo no wipers ....just fast...

What will change....

I like my Cobras to be blue.....So I will be smoothing the body,and taking care of a few spider cracks before painting it sunset blue pearl with a white stripe...

The car came with a hideous Pinto/Mustang 2 shifter that has to go...I bought a Hurst Quarter stick shifter for it ....

The engine compt will be detailed .......The chassis will be detailed and painted as well...

The Sidepipes and headers are hot coated

I will be posting the progress...

Here are the before Pics...

Attachments

-

181DSCF0013co.jpg112.4 KB · Views: 535

181DSCF0013co.jpg112.4 KB · Views: 535 -

181DSCF0023co.jpg116.5 KB · Views: 716

181DSCF0023co.jpg116.5 KB · Views: 716 -

181DSCF0022co.jpg117.9 KB · Views: 930

181DSCF0022co.jpg117.9 KB · Views: 930 -

181DSCF0021co.jpg119.5 KB · Views: 518

181DSCF0021co.jpg119.5 KB · Views: 518 -

181DSCF0020co.jpg104.8 KB · Views: 515

181DSCF0020co.jpg104.8 KB · Views: 515 -

181DSCF0019co.jpg102.4 KB · Views: 803

181DSCF0019co.jpg102.4 KB · Views: 803 -

181DSCF0018co.jpg122.9 KB · Views: 530

181DSCF0018co.jpg122.9 KB · Views: 530 -

181DSCF0015co.jpg90.1 KB · Views: 539

181DSCF0015co.jpg90.1 KB · Views: 539

Last edited: