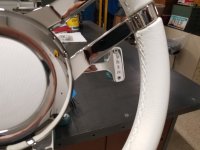

Hey guys, I'll apologize in advance for being long winded. The boat has a two ram add on kit and I'm finally getting around to upgrading to full hydraulic. The biggest problem I've needed to sort out is how to deal with the trim control. Currently, trim switch is mounted on the steering wheel, which we've come to like except for when you need to make a trim adjustment and the wheel is half turned so the switch is upside down and backward. Bare with me, more to come, and I dont think it will disappoint. Thanks for reading

Attachments

Last edited: