Bigbore500r

Well-Known Member

- Joined

- Apr 28, 2014

- Messages

- 18,588

- Reaction score

- 39,810

Several people on here have had GM motors in their trucks go out with a bad lifter. Most just buy a new motor and have it installed to the tune of $5000 - but I'm a cheap ass gear head, and I'm gonna show you how to fix it instead and add some horsepower at the same time.

My friends 2008 Silverado had a lifter go out at 170k miles. Motor always ran good and didn't use any oil, until the lifter went kaboom. We tore it down to inspect. The lifter failure was limited to just a collapse of the internal lifter AFM mechanism (cylinder deactivation assembly inside the lifter) and did not damage the cam lobe or block. We could have just replaced the lifters with a new set and slapped the heads back on....but what fun is that? Instead we decided on some upgrades while we were in there, to add some horsepower for towing duty and freshen the motor up a bit.

The plan:

-Rebuild the heads

-Deck the heads .030

-Install LS6 valve springs

-Delete the cylinder deactivation junk

-Cam swap / upgrade

-Custom tune

Here we go..........

Once torn down....the culprit lifter is identified. You can see here it is "collapsed" and shorter than the one next to it. This was the tapping that was heard. The motor was not damaged (even the cam was ok) because it wasn't driven home....it was towed once the noise started.

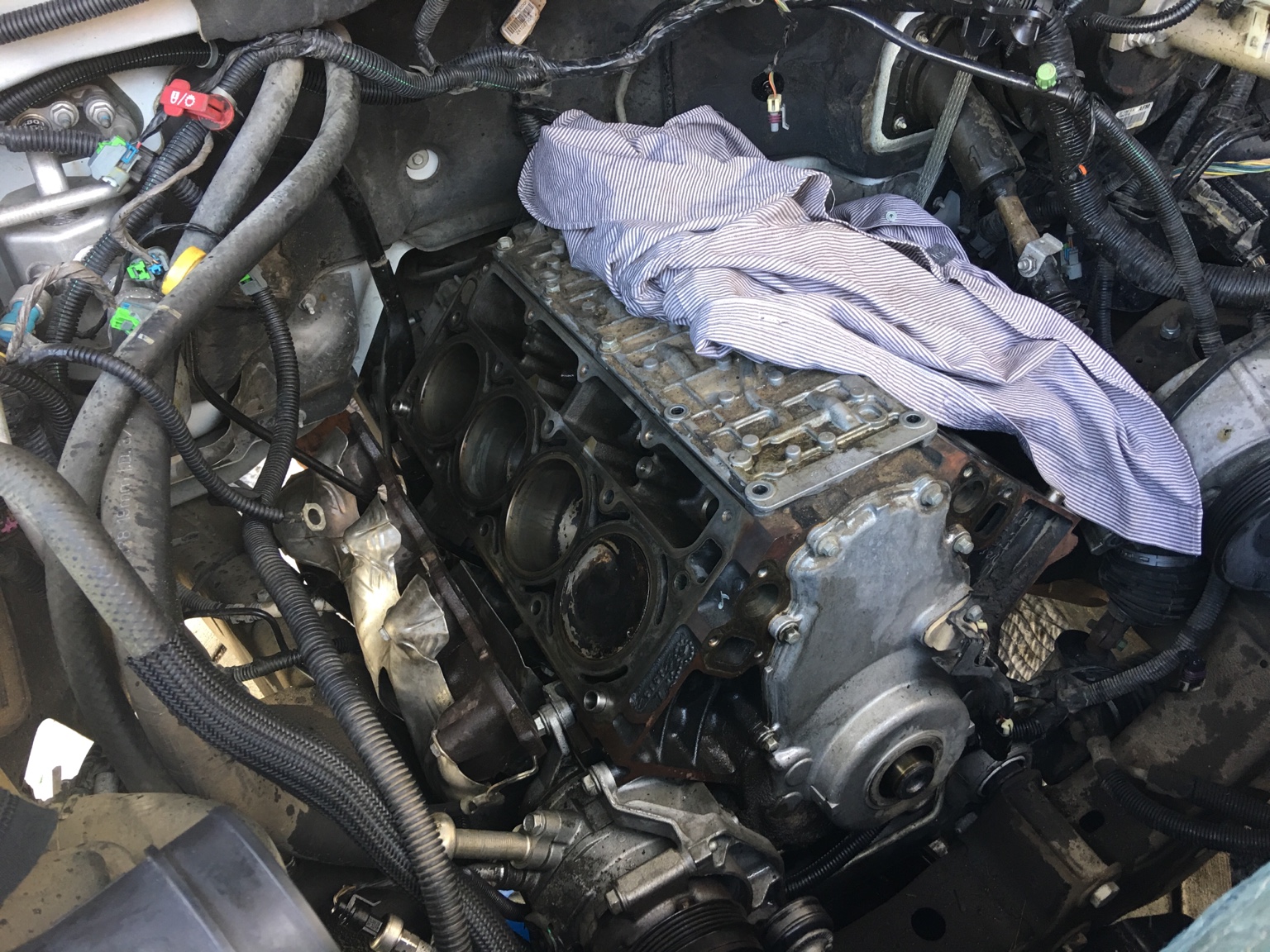

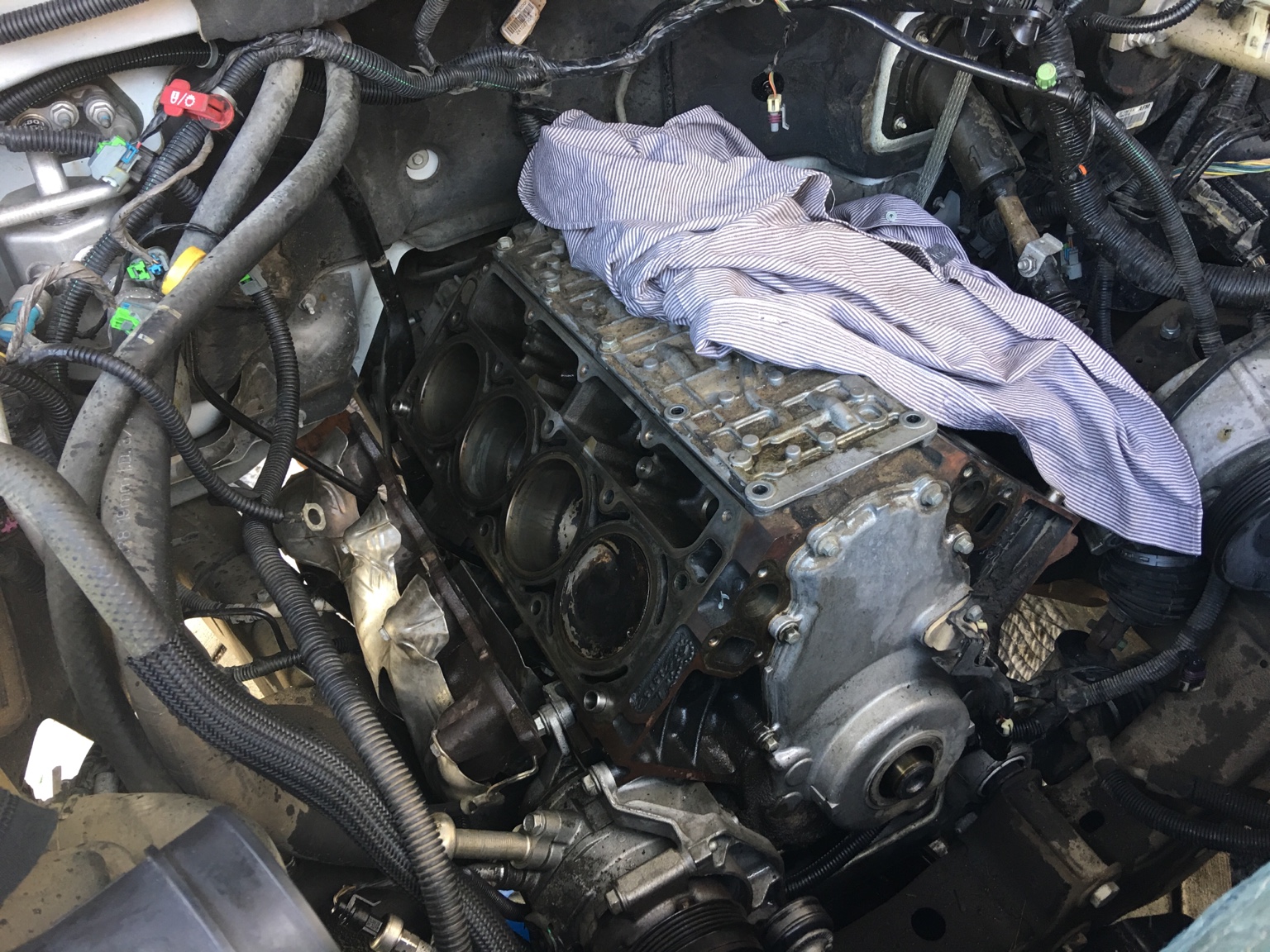

Here is the 170k motor...torn down to the shortblock. It's just a wee baby and ready for some more HP. Now I know what you Ford guys are thinking - Jerry, isn't it about dead at 170k? No Ford guys.....this is a god damn Chevy Silverado. It's got a Vortec engine, made from big dicks and real tornadoes [emoji3]

So what kills the lifters in these 07+ trucks with cylinder deactivation? Well....nothing lasts forever, but they do have an issue and its this little baby right here -A fine screen that is designed to prevent debris from entering the AFM solonoids in the lifter valley. Problem is...the screen is too fine and becomes gummed up, usually by the 60k mile mark. Once this happens it begins starving the AFM lifters for oil, and the mechanism inside the lifter eventually fails.

See the screen here, located under the oil pressure sensor. You can easily get rid of this screen and prevent this btw....

Here is some of the stuff we are deleting - we are getting rid of the lifter valley cover and all the attached AFM solenoids you see here.

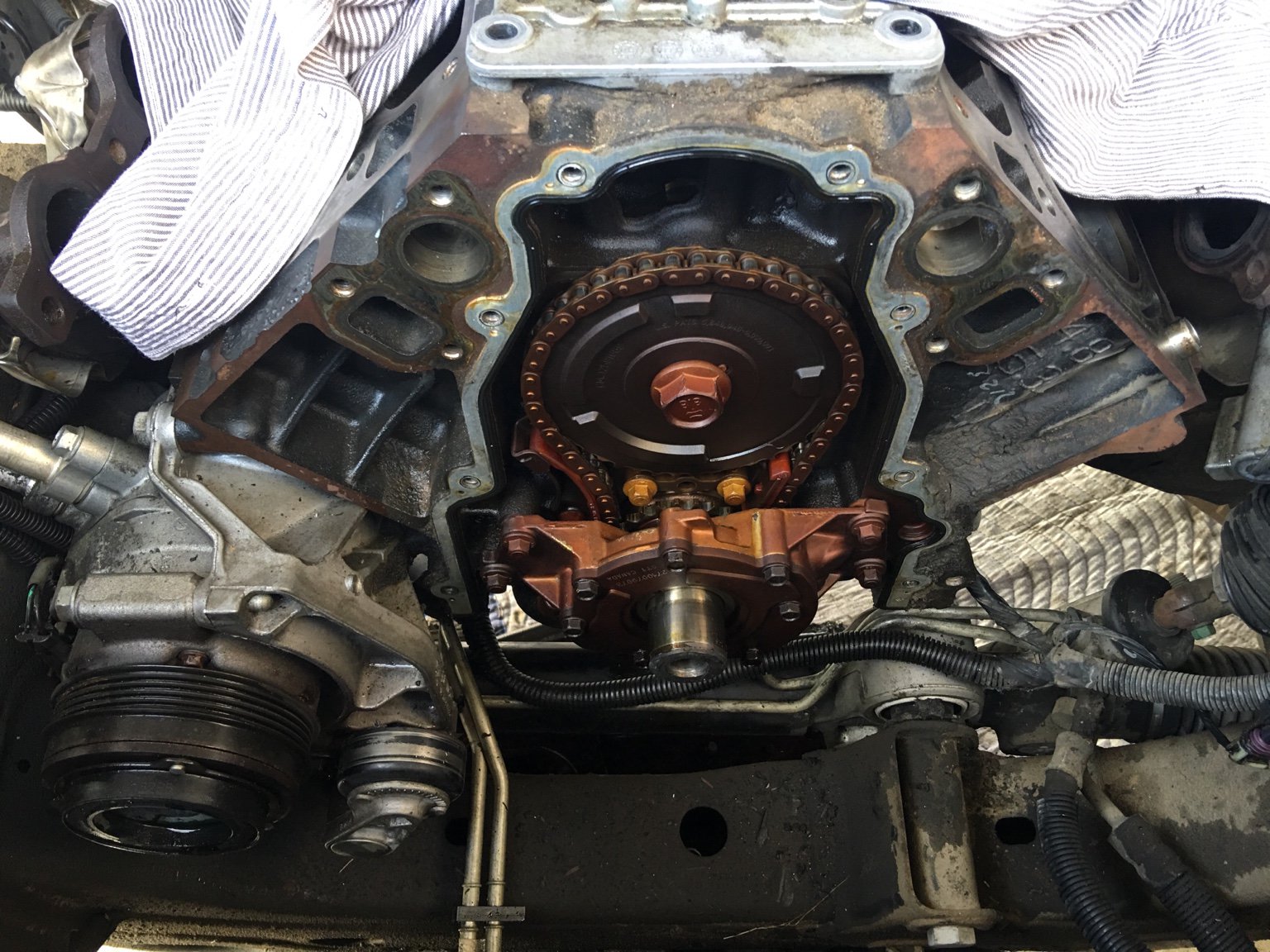

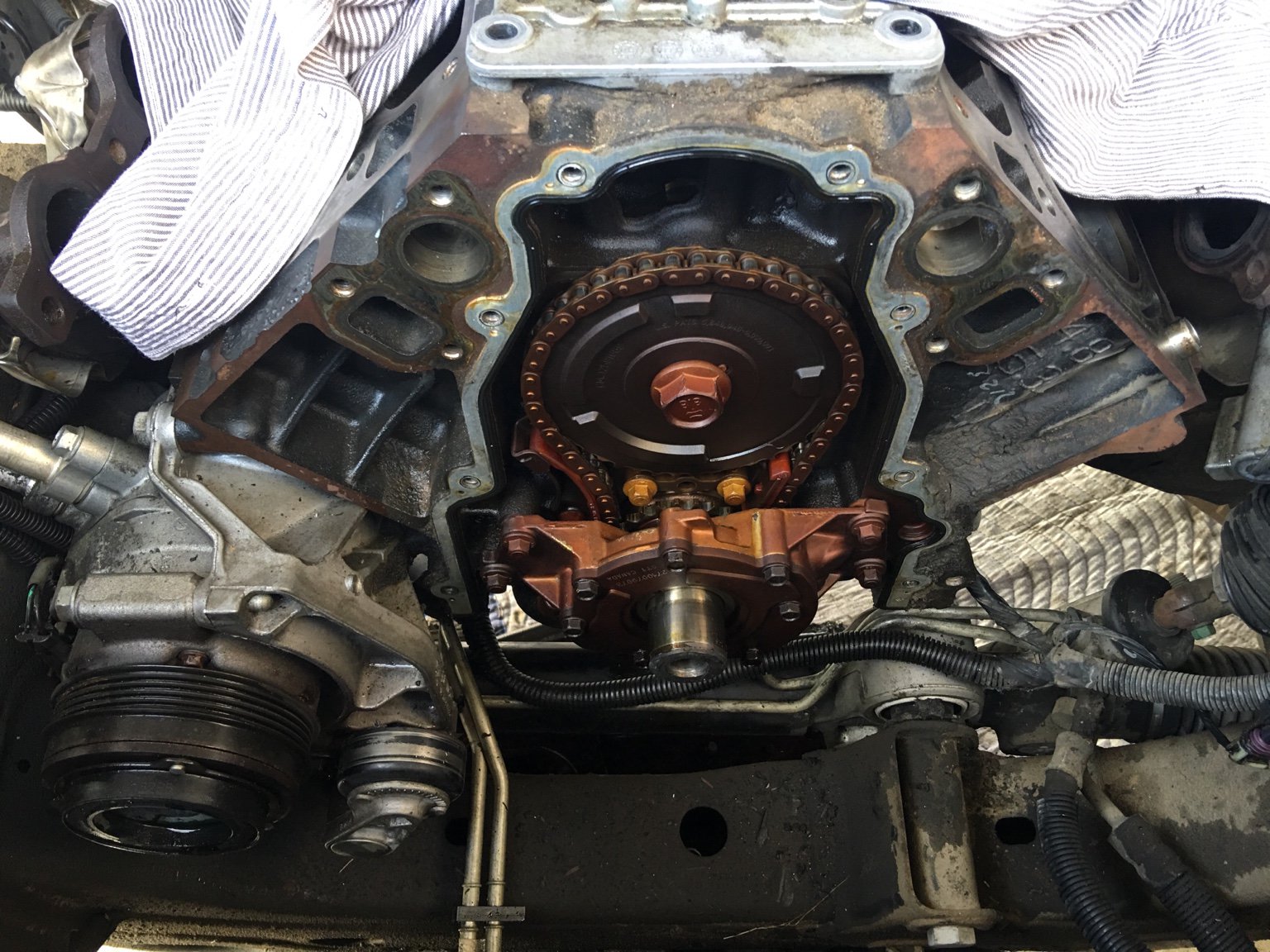

Here is the stock timing set. Note the spring loaded chain damper and single bolt cam sprocket. All of this is going bye - bye

Here is the new cam. It's a small grind designed to boost power everywhere without any low end torque loss. 210 / 216 .550 .550 112lsa.

Once the new cam is in, the new timing set goes on. This is a LS2 GM chain, and the cam gear is a 2005-2008 C6 corvette piece that accepts the 3 bolt cam fasteners, yet still has the proper cam sensor pickup points for the Gen IV motors. Note that the spring loaded tensioner is history - it's replaced with a more reliable LS2 style damper block. The spring loaded tensioners on the 07-up motors are known to come apart, so we swapped that junk out to the LS2 neoprene damper that never dies. Cam sprocket gets 3 ARP cam bolts.

The oil pan and pump were removed to allow the timing chain to be replaced. To reassemble, a new Oil pump pickup Oring is installed. These are the #1 cause for oil pressure issues when these motors get close to 200k miles. You have to be sure to get the proper Oring, they vary depending on pickup tube type!

Once the cam is all buttoned up, and oil pump is back on, we install the new lifters. These are GM LS7 lifters, and the plastic "trays" you see here are what keep them aligned in the block. These trays are also new, as the originals from the AFM lifters do not work with the "standard non AFM" style lifters. All traces of cylinder deactivation are now gone.

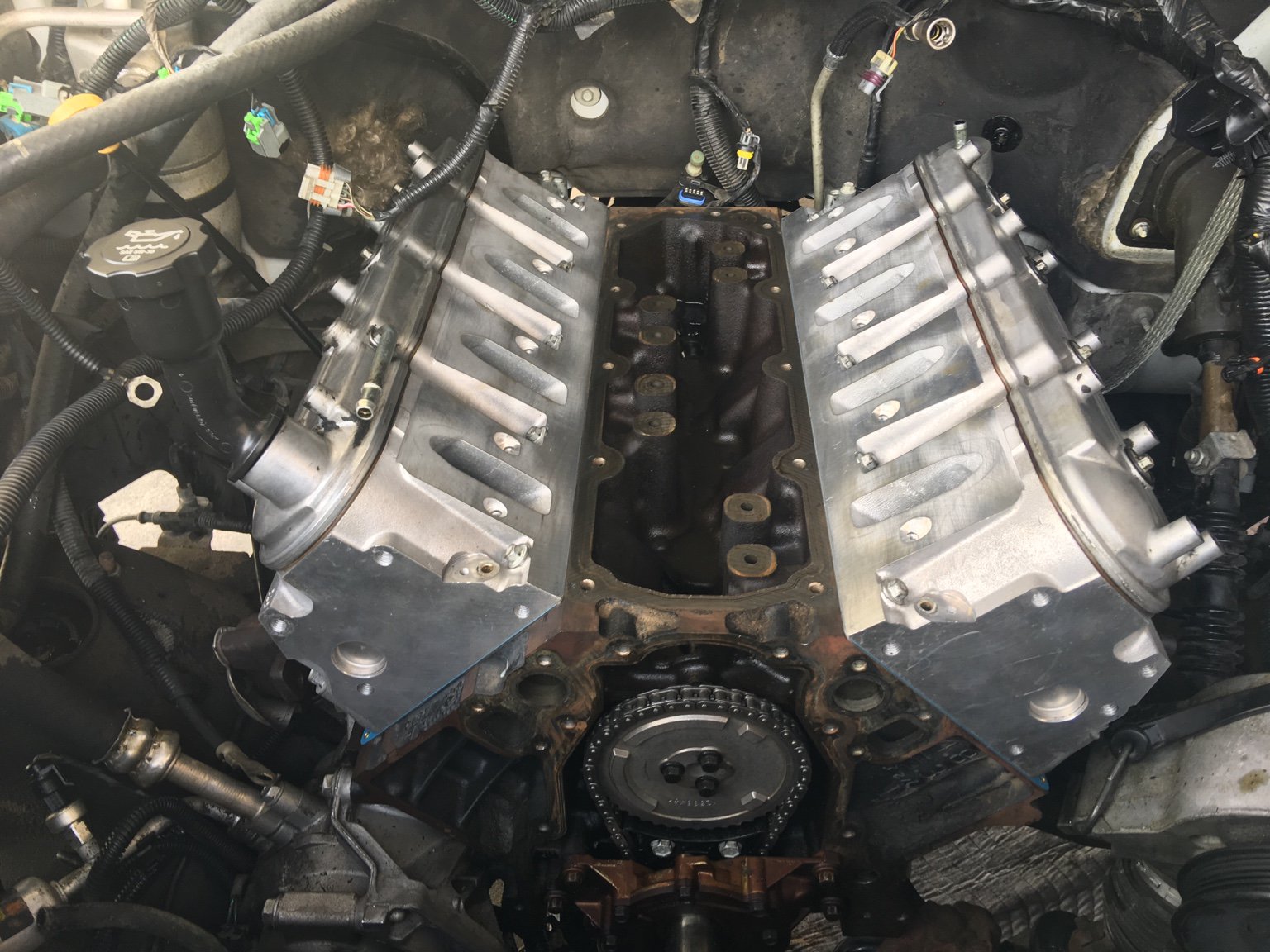

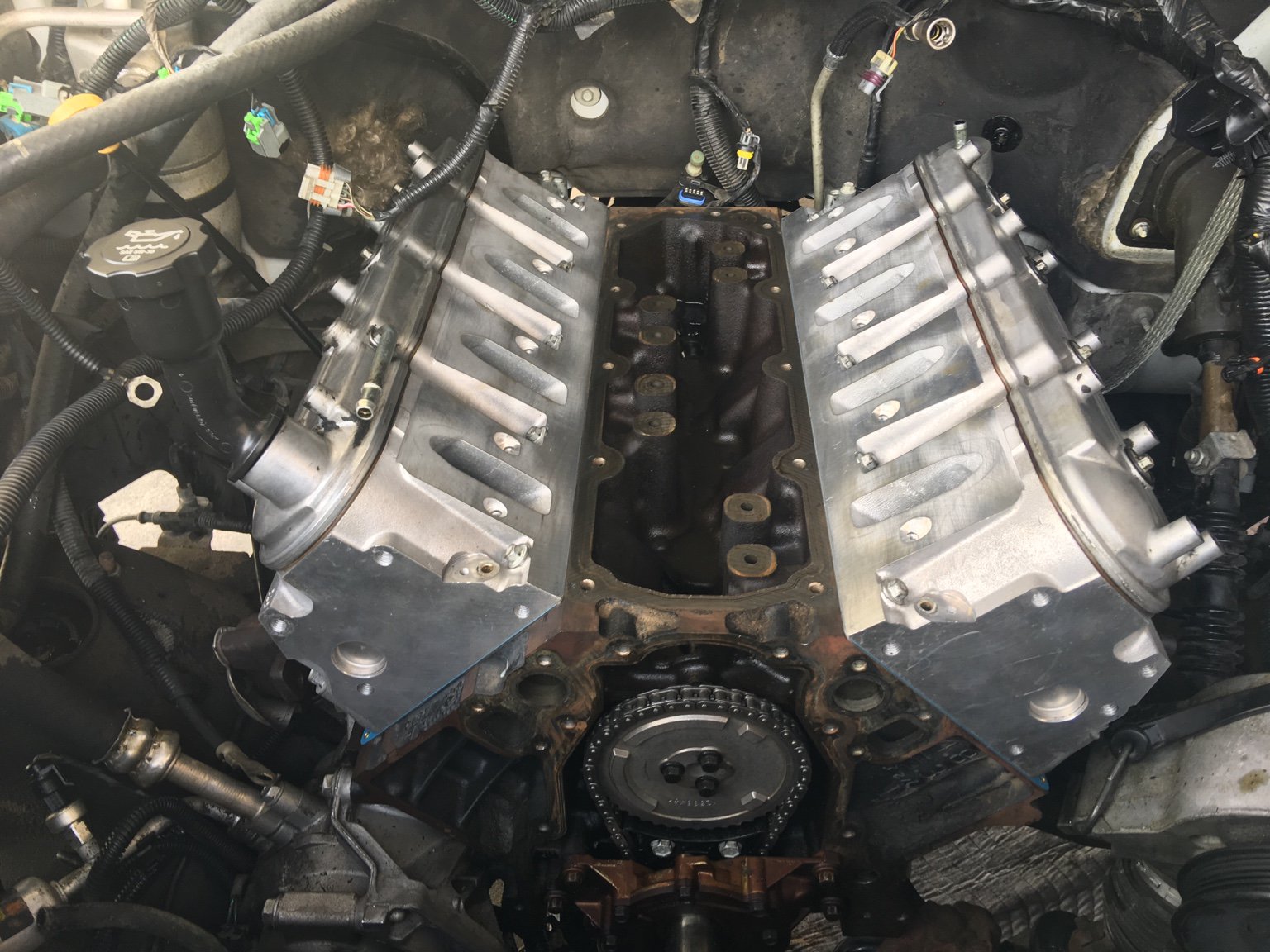

We took the opportunity to freshen up the cylinder heads while they were off. The heads that come on these later model 4.8 / 5.3 are the same heads used on the LS2 and LS6 motors. You can easily make power with these babies. Heads were decked .025 to bring the compression up, and to also avoid the need for .025 longer pushrods due to the smaller base circle of the new camshaft. This keeps the lifter preload where it needs to be. Aside from that, new seals were installed as well as a valve job. A radius cut was put on the exhaust seat to improve the flow. A set of GM LS2 / LS3 / LS6 valve springs were installed to work with the new camshaft, which has .550 lift at the valve

Once the heads are back on, they are torqued down with new head bolts. The holes are blind tapped in the block, and must be cleaned and chased / blown out with compressed air before the new bolts go in. If you fail to do this, you will get an improper torque of the new bolts, or if your real lucky it will break off in the block which is a nightmare. The aluminum block motors can actually have the block split and be damaged by improper head bolt installation without cleaning the holes. Clean the surface of the block before you clean the bolt holes out, so you aren't knocking shit back into the clean bolt holes while scraping the deck.

Here the heads are on and torqued...and the pushrods and rocker arm assembly are back in place. No preload adjustment is present with the stock rockers, just torque them down to spec. I check preload with the cam off the lobe, and from zero lash you should get between 1.25 and 1.75 turns till full torque value. If you have less than 1 turn - you need longer pushrods. More than 1.75 turns....you need shorter pushrods. We ended up @ 1.5 turns here, which is about what it would be stock. We decked the heads the same amount as the base circle is reduced on the new cam (experience has shown me this particular cam measures out at that spec) so we are right where we need to be.

Valve covers are also back on here

Once the heads are on....the new LS3 lifter valley cover goes on. This cover has the necessary O-rings on the bottom to block off the AFM oil passages that are now abandoned. It comes with the block gasket as well. The original oil pressure sender goes back on. You can see the baffled breather setup on the bottom of the cover as well. This helps control oil ingestion at high rpm.

The timing cover and balancer go back on. The cover must be aligned with a tool to ensure the balancer seal aligns with the snout of the balancer / crank pulley. The oil pan is then reinstalled, and a little black engine paint is tossed in to dress the greaseball up a bit.

Next step will be a dyno tune to delete all the AFM codes that will be present, and recalibrate the fuel and spark tables for the new cam and increased compression. This will still pass smog, and will idle almost like 100% stock with slightly more rpm. I'll post up the dyno graph once we get it tuned up.

Labor involved in this is 12 beer drinking hours on a Sunday (with all parts ready to go). I do these a lot so it may take somebody else a bit longer, but it's not bad.

Hope you enjoyed....stay tuned for the dyno test. We'll compare the rwhp and torque readings to a stock baseline, and also see how it stacks up against the vaunted 6.0. We'll also see how it compares to a new 2015 Silverado 5.3 Ecotec. Can this little beater put up the numbers?

My friends 2008 Silverado had a lifter go out at 170k miles. Motor always ran good and didn't use any oil, until the lifter went kaboom. We tore it down to inspect. The lifter failure was limited to just a collapse of the internal lifter AFM mechanism (cylinder deactivation assembly inside the lifter) and did not damage the cam lobe or block. We could have just replaced the lifters with a new set and slapped the heads back on....but what fun is that? Instead we decided on some upgrades while we were in there, to add some horsepower for towing duty and freshen the motor up a bit.

The plan:

-Rebuild the heads

-Deck the heads .030

-Install LS6 valve springs

-Delete the cylinder deactivation junk

-Cam swap / upgrade

-Custom tune

Here we go..........

Once torn down....the culprit lifter is identified. You can see here it is "collapsed" and shorter than the one next to it. This was the tapping that was heard. The motor was not damaged (even the cam was ok) because it wasn't driven home....it was towed once the noise started.

Here is the 170k motor...torn down to the shortblock. It's just a wee baby and ready for some more HP. Now I know what you Ford guys are thinking - Jerry, isn't it about dead at 170k? No Ford guys.....this is a god damn Chevy Silverado. It's got a Vortec engine, made from big dicks and real tornadoes [emoji3]

So what kills the lifters in these 07+ trucks with cylinder deactivation? Well....nothing lasts forever, but they do have an issue and its this little baby right here -A fine screen that is designed to prevent debris from entering the AFM solonoids in the lifter valley. Problem is...the screen is too fine and becomes gummed up, usually by the 60k mile mark. Once this happens it begins starving the AFM lifters for oil, and the mechanism inside the lifter eventually fails.

See the screen here, located under the oil pressure sensor. You can easily get rid of this screen and prevent this btw....

Here is some of the stuff we are deleting - we are getting rid of the lifter valley cover and all the attached AFM solenoids you see here.

Here is the stock timing set. Note the spring loaded chain damper and single bolt cam sprocket. All of this is going bye - bye

Here is the new cam. It's a small grind designed to boost power everywhere without any low end torque loss. 210 / 216 .550 .550 112lsa.

Once the new cam is in, the new timing set goes on. This is a LS2 GM chain, and the cam gear is a 2005-2008 C6 corvette piece that accepts the 3 bolt cam fasteners, yet still has the proper cam sensor pickup points for the Gen IV motors. Note that the spring loaded tensioner is history - it's replaced with a more reliable LS2 style damper block. The spring loaded tensioners on the 07-up motors are known to come apart, so we swapped that junk out to the LS2 neoprene damper that never dies. Cam sprocket gets 3 ARP cam bolts.

The oil pan and pump were removed to allow the timing chain to be replaced. To reassemble, a new Oil pump pickup Oring is installed. These are the #1 cause for oil pressure issues when these motors get close to 200k miles. You have to be sure to get the proper Oring, they vary depending on pickup tube type!

Once the cam is all buttoned up, and oil pump is back on, we install the new lifters. These are GM LS7 lifters, and the plastic "trays" you see here are what keep them aligned in the block. These trays are also new, as the originals from the AFM lifters do not work with the "standard non AFM" style lifters. All traces of cylinder deactivation are now gone.

We took the opportunity to freshen up the cylinder heads while they were off. The heads that come on these later model 4.8 / 5.3 are the same heads used on the LS2 and LS6 motors. You can easily make power with these babies. Heads were decked .025 to bring the compression up, and to also avoid the need for .025 longer pushrods due to the smaller base circle of the new camshaft. This keeps the lifter preload where it needs to be. Aside from that, new seals were installed as well as a valve job. A radius cut was put on the exhaust seat to improve the flow. A set of GM LS2 / LS3 / LS6 valve springs were installed to work with the new camshaft, which has .550 lift at the valve

Once the heads are back on, they are torqued down with new head bolts. The holes are blind tapped in the block, and must be cleaned and chased / blown out with compressed air before the new bolts go in. If you fail to do this, you will get an improper torque of the new bolts, or if your real lucky it will break off in the block which is a nightmare. The aluminum block motors can actually have the block split and be damaged by improper head bolt installation without cleaning the holes. Clean the surface of the block before you clean the bolt holes out, so you aren't knocking shit back into the clean bolt holes while scraping the deck.

Here the heads are on and torqued...and the pushrods and rocker arm assembly are back in place. No preload adjustment is present with the stock rockers, just torque them down to spec. I check preload with the cam off the lobe, and from zero lash you should get between 1.25 and 1.75 turns till full torque value. If you have less than 1 turn - you need longer pushrods. More than 1.75 turns....you need shorter pushrods. We ended up @ 1.5 turns here, which is about what it would be stock. We decked the heads the same amount as the base circle is reduced on the new cam (experience has shown me this particular cam measures out at that spec) so we are right where we need to be.

Valve covers are also back on here

Once the heads are on....the new LS3 lifter valley cover goes on. This cover has the necessary O-rings on the bottom to block off the AFM oil passages that are now abandoned. It comes with the block gasket as well. The original oil pressure sender goes back on. You can see the baffled breather setup on the bottom of the cover as well. This helps control oil ingestion at high rpm.

The timing cover and balancer go back on. The cover must be aligned with a tool to ensure the balancer seal aligns with the snout of the balancer / crank pulley. The oil pan is then reinstalled, and a little black engine paint is tossed in to dress the greaseball up a bit.

Next step will be a dyno tune to delete all the AFM codes that will be present, and recalibrate the fuel and spark tables for the new cam and increased compression. This will still pass smog, and will idle almost like 100% stock with slightly more rpm. I'll post up the dyno graph once we get it tuned up.

Labor involved in this is 12 beer drinking hours on a Sunday (with all parts ready to go). I do these a lot so it may take somebody else a bit longer, but it's not bad.

Hope you enjoyed....stay tuned for the dyno test. We'll compare the rwhp and torque readings to a stock baseline, and also see how it stacks up against the vaunted 6.0. We'll also see how it compares to a new 2015 Silverado 5.3 Ecotec. Can this little beater put up the numbers?