Not that we will have a follow up Friday every week, but last weeks article "The Down Pedal" (Click that link to read) Got quite a bit of response, so we decided to dig a little deeper! Clyde Church was kind enough to send us some up close pictures of his system, and some more detailed explanations of how some of it works.

Now looking at some of these things without knowing what they are it can be a little overwhelming at a glance, but if you kind of take it apart piece by piece, I think you will see that the system itself is actually quite simple in how it works, and not intimidating at all. I will say in advance this is one of those situations where a picture is going to have to be worth a thousand words. I have written it out a couple of different times now, and by the time I was finished the text was more confusing then just following along with the pictures.

The system is comprised of three main components when you break it down.

Part one is the Air Tank and associated components.

These are "filament wound" air tanks that are different then traditional "metal" tanks like Scuba tanks. They can be made up of wire, carbon fiber or a host of other materials. They are extremely light weight, and hold more capacity then traditional tanks. The reason they can be thin and light weight is because they take a strand of material (wire / carbon fiber etc.) and they begin wrapping it around a cylinder, and finish by wrapping it around the ends. When you pressurize the tank it puts that strand in "tension." So Imagine a rope here for a second. A rope is flexible in every direction, but only strong when you pull it. This allows the tank to be thinner (which equals more capacity) and lighter because there is less material. They are also considerably safer because in the event of a failure, they basically just leave a frayed piece of fabric behind, where as a traditional (thick walled metal tank) turns into a bomb or a rocket when they fail.

To the right of that you are going to have a pressure gauge showing the Tank pressure. To the right of that you are going to have a pressure regulator that is going to dial down the 3000 PSI pressure to whatever pressure you want it to be. I forgot to ask Clyde what the operating pressures of this system are, but I'd imagine it would be variable from 80-150 PSI. The higher the pressure you have it set at, the easier the pedal is going to be to push. On that same token the higher the pressure, the faster the air tank will run out.

Above the pressure regulator you are going to have another Pressure Gauge showing you your output pressure, and then again to the right of that is your air outlet that will run back to the second component of the system.

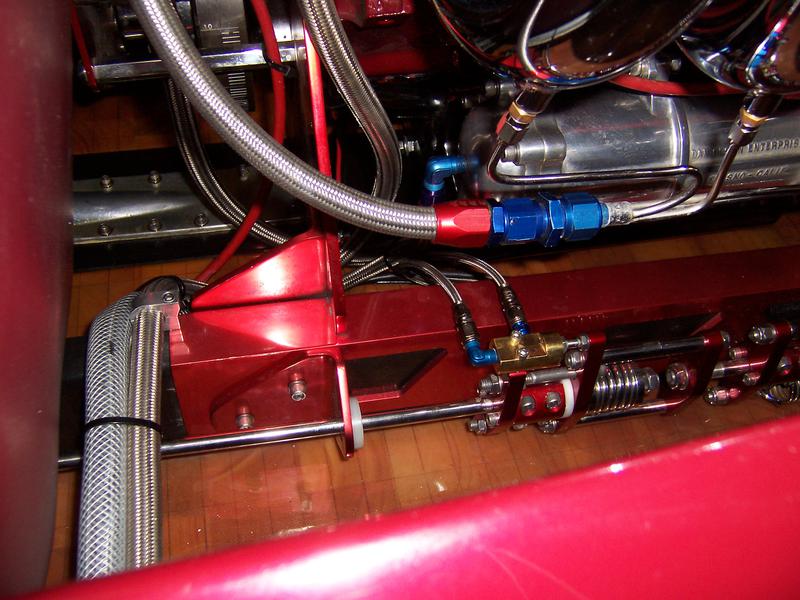

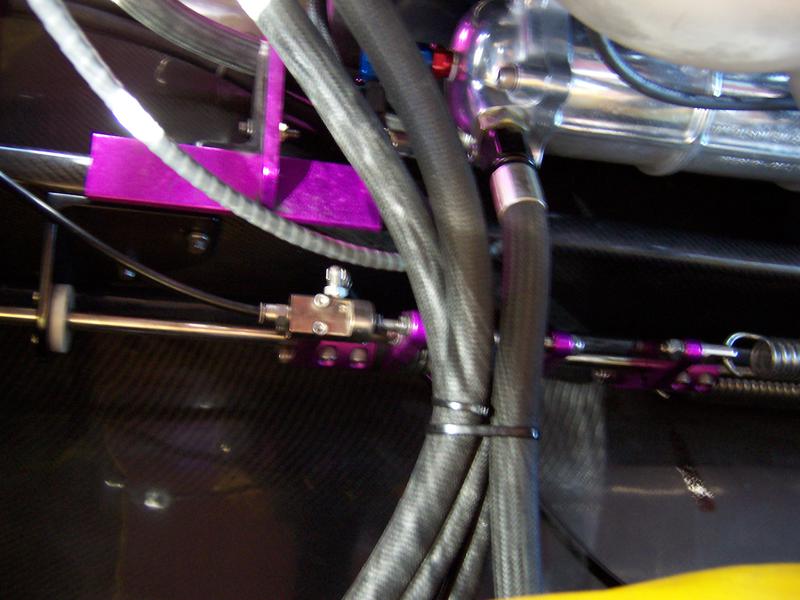

This is probably the most complex part of the system itself and where I'm going to let the picture do most the talking. In short I wrote it out a couple of times and it's easier to just say "this is how it works look at the picture" then writing it all out in text. If you are too look at the picture though, the most important thing to realize right off the bat is that round piece at the very top of the picture is a manual air valve. In that Photo you are going to see four plates that from left to right we will reference one through four. Plates number one and two move independently of each other, and that is what pushes on that air valve. When the valve opens it sends the air back to the cylinder that actually assists in the operation (assembly number three). Everything else in that picture in the center has to do with allowing the plates to move independently, and transferring loads back to the back plate to keep everything functioning as one. The center piece that you see with the spring and that small gap is the adjustment to determine when the system turns on (larger the gap the longer before it does, and the smaller the gap the inverse). The spring itself is to manually reset the air valve.

The Third Component of the system is just the Cylinder that rests "inline" towards the rear of the boat.

You can see the traditional large "return springs" that would pull the plates up on a v-drive. In the middle you can see there is an air cylinder with a rod coming out both ends of it. You would connect the rod coming out the back to your traditional linkage towards the transom of the boat. On the air cylinder in this picture you can see the front port still has the red plastic cover on it. This would be removed, and vented to atmosphere. Clyde mentioned to me on the phone that they like to run a little hose to a filter and mount it up higher just so when the piston is stroking in and out it doesn't accidentally suck up some water in there and cause corrosion. For a traditional "down pedal assist" system we are only going to be using the rear port. I wish I had a better picture, but if you look closely to the right of the cylinder you will see a 3 way fitting AKA a "T Fitting." One side of the "T" is going into the air cylinder, the other two sides of the "T" are going to be connected to the air valve in the front.

(Picture of the Entire system inline)

When the system is actuated the air valve is going to open sending air pressure down the line and into the air cylinder pushing the piston forward and helping to pull the rod forward. When you release the pedal back to rest the air valve will side over and close the output to the cylinder and open another port to atmosphere. The air will then return out of the cylinder and go out the side of the T back to the air valve and vent to atmosphere.

That in short is how the basic air system works. It should be noted that for some circle boat applications they actually put a restriction on the airline that would exhaust when the system is released. This helps to slightly slow the return of the plates in the event that your foot should slide off the pedal. In Drag racing applications, they don't actually run the airline back to the air valve itself, but instead put a small independent valve right on the cylinder to maximize air flow on the exhaust so that the pedals can come up quicker. Now without chasing this thing completely down the rabbit hole, on some K Boat or Australian "Tuff Boat" applications, they will actually plumb the front port on the air cylinder as well and use a "button" on the steering wheel to reverse the system and add assist to keep the plates all the way up!!

I realize that in text it's probably a little confusing, but I hope to have helped to educate those that were interested in how this particular "Assist" system works in some of the faster V-drives that you will see at the races, and on the river.

Clyde in his boat with his son

The very first Air Assist system installed on his ride.

Dave Rankin's circle boat with Air Assist

Compoenent 1

Component 1

Component 2 & 3 (partially hidden by hoses)

Now looking at some of these things without knowing what they are it can be a little overwhelming at a glance, but if you kind of take it apart piece by piece, I think you will see that the system itself is actually quite simple in how it works, and not intimidating at all. I will say in advance this is one of those situations where a picture is going to have to be worth a thousand words. I have written it out a couple of different times now, and by the time I was finished the text was more confusing then just following along with the pictures.

The system is comprised of three main components when you break it down.

Part one is the Air Tank and associated components.

These are "filament wound" air tanks that are different then traditional "metal" tanks like Scuba tanks. They can be made up of wire, carbon fiber or a host of other materials. They are extremely light weight, and hold more capacity then traditional tanks. The reason they can be thin and light weight is because they take a strand of material (wire / carbon fiber etc.) and they begin wrapping it around a cylinder, and finish by wrapping it around the ends. When you pressurize the tank it puts that strand in "tension." So Imagine a rope here for a second. A rope is flexible in every direction, but only strong when you pull it. This allows the tank to be thinner (which equals more capacity) and lighter because there is less material. They are also considerably safer because in the event of a failure, they basically just leave a frayed piece of fabric behind, where as a traditional (thick walled metal tank) turns into a bomb or a rocket when they fail.

To the right of that you are going to have a pressure gauge showing the Tank pressure. To the right of that you are going to have a pressure regulator that is going to dial down the 3000 PSI pressure to whatever pressure you want it to be. I forgot to ask Clyde what the operating pressures of this system are, but I'd imagine it would be variable from 80-150 PSI. The higher the pressure you have it set at, the easier the pedal is going to be to push. On that same token the higher the pressure, the faster the air tank will run out.

Above the pressure regulator you are going to have another Pressure Gauge showing you your output pressure, and then again to the right of that is your air outlet that will run back to the second component of the system.

This is probably the most complex part of the system itself and where I'm going to let the picture do most the talking. In short I wrote it out a couple of times and it's easier to just say "this is how it works look at the picture" then writing it all out in text. If you are too look at the picture though, the most important thing to realize right off the bat is that round piece at the very top of the picture is a manual air valve. In that Photo you are going to see four plates that from left to right we will reference one through four. Plates number one and two move independently of each other, and that is what pushes on that air valve. When the valve opens it sends the air back to the cylinder that actually assists in the operation (assembly number three). Everything else in that picture in the center has to do with allowing the plates to move independently, and transferring loads back to the back plate to keep everything functioning as one. The center piece that you see with the spring and that small gap is the adjustment to determine when the system turns on (larger the gap the longer before it does, and the smaller the gap the inverse). The spring itself is to manually reset the air valve.

The Third Component of the system is just the Cylinder that rests "inline" towards the rear of the boat.

You can see the traditional large "return springs" that would pull the plates up on a v-drive. In the middle you can see there is an air cylinder with a rod coming out both ends of it. You would connect the rod coming out the back to your traditional linkage towards the transom of the boat. On the air cylinder in this picture you can see the front port still has the red plastic cover on it. This would be removed, and vented to atmosphere. Clyde mentioned to me on the phone that they like to run a little hose to a filter and mount it up higher just so when the piston is stroking in and out it doesn't accidentally suck up some water in there and cause corrosion. For a traditional "down pedal assist" system we are only going to be using the rear port. I wish I had a better picture, but if you look closely to the right of the cylinder you will see a 3 way fitting AKA a "T Fitting." One side of the "T" is going into the air cylinder, the other two sides of the "T" are going to be connected to the air valve in the front.

(Picture of the Entire system inline)

When the system is actuated the air valve is going to open sending air pressure down the line and into the air cylinder pushing the piston forward and helping to pull the rod forward. When you release the pedal back to rest the air valve will side over and close the output to the cylinder and open another port to atmosphere. The air will then return out of the cylinder and go out the side of the T back to the air valve and vent to atmosphere.

That in short is how the basic air system works. It should be noted that for some circle boat applications they actually put a restriction on the airline that would exhaust when the system is released. This helps to slightly slow the return of the plates in the event that your foot should slide off the pedal. In Drag racing applications, they don't actually run the airline back to the air valve itself, but instead put a small independent valve right on the cylinder to maximize air flow on the exhaust so that the pedals can come up quicker. Now without chasing this thing completely down the rabbit hole, on some K Boat or Australian "Tuff Boat" applications, they will actually plumb the front port on the air cylinder as well and use a "button" on the steering wheel to reverse the system and add assist to keep the plates all the way up!!

I realize that in text it's probably a little confusing, but I hope to have helped to educate those that were interested in how this particular "Assist" system works in some of the faster V-drives that you will see at the races, and on the river.

Clyde in his boat with his son

The very first Air Assist system installed on his ride.

Dave Rankin's circle boat with Air Assist

Compoenent 1

Component 1

Component 2 & 3 (partially hidden by hoses)