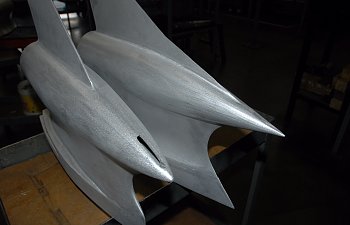

(New Dual Down Shaft Lower Assembled)

Ask any marine repair shop involved in routinely servicing high performance boats,

engines and propulsion systems….“what’s the single most abused and broken

component encountered on a regular basis?” That’s easy, the standard Mercury Bravo

One sterndrive.

When Mercury introduced the Bravo One back in 1988 (replacing the TRS drive), it was

mated to a 330 horsepower 7.4L (454 c.i.) GM V-8 block. For some boaters, the stock

engine package didn’t pack enough punch, and the quest for more horsepower and

torque was on, and it hasn’t stopped.

To Mercury’s credit, they’ve made attempts over the past 30 years to introduce better,

stronger, more durable versions of the Bravo by developing the XR and XZ models.

Improved and beefier internal components like upgraded straight-cut gears, shafts and

bearings helped the XR and XZ drives, but it was never enough to keep pace with the

hot rod water crowd who ignore factory recommended Bravo max horsepower and

torque limits. According to IMCO, the majority of Bravo style drive failures occur at

about 3,500 to 4,000 rpm when engines are delivering their maximum torque output or

during hammer-down acceleration.

(Top view of SCX gearcase with machined holes for downshafts.)

So, the mechanical carnage caused by excessive power has become an accepted fact

of high performance Bravo boating. Those who tried to beat the system either turned to

aftermarket companies building hybrid Bravo type drives on steroids or took the leap to

Mercury Racing number Six or M8 drives causing a significant dent in their wallet.

Unbeknownst to most everyone in the performance marine industry, IMCO Marine,

already well known for its SC, SCX and SCX4 drive options, has been developing

something brand new over the past 18 months, targeted to bridge that gap in the Bravo

market between 600 to 1000 (possibly more) horsepower. Some might call it the

“missing link.” It’s the new IMCO SCX “Dual Downshaft.”

(Dual custom precision ground, not cut, spur gears.

Before getting into the details of the new drive, proper appreciation of the development

and engineering process that went into this project is in order. First, it was developed

and engineered in-house using CAD software. But it didn’t stop there. A little over a year

ago, IMCO invested a considerable sum of money in a high-end 3D printer. As the

engineering unfolded, what was on the computer monitor was ‘printed-out’ as full-size

actual parts in plastic before any of the machining or mold making began. So much for

wasteful trial and error.

(In-house IMCO 3D printer)

So here’s the concept behind the “Dual Downshaft”. As more boaters cram more

horsepower into the engine compartment, conventional single vertical downshaft Bravos

kill the relatively small lower unit gears. Serial abusers find a way to repeatedly tear-up

new gear sets in duty-cycles of less than 30 or 40 hours, and sometimes even less.

With only one standard downshaft and single gear to gear contact mandated by the tight

confines of the Bravo gearcase however, installing bigger, more heavy-duty gears are

not a feasible solution as long as the stock Bravo lower unit wants to maintain its slim

and efficient external profile.

(SCX 1-1/4” propshaft with two sets of gears ready for dual downshafts.)

Recognizing the durability superiority of Mercury Racing’s number Six and M8 drives,

also with dual downshafts allowing massive torque loads to be spread thus resulting in

less gear wear and fatigue, creating a Bravo style lower with twin downshafts was

IMCO’s answer to achieve greater strength, more reliability and longer duty-cycles with

higher output engines.

Here are some things to remember however. First, the new IMCO “Dual Downshaft” is

only compatible with an IMCO SCX upper. Next, it is not intended to be applied as a

‘surfacing’ drive like the SCX4. For that reason, the “Dual Downshaft” is intended

primarily for use on single engine air entrapment/cat hulls (especially deckboats) with

massive horsepower or vee-bottoms with big output twin or single powerplant

applications. The “Dual Downshaft” is two-inches shorter than a stock Bravo and retains

an internal shifting cone-clutch (no external transmission needed) and utilizes

conventional wet sump lubrication. The propshaft is 1-1/4-inch, however a 1-7/16-inch

propshaft option may be offered in the future. All IMCO SCX gear ratios are available.

Internally, IMCO has integrated a number of ingenious solutions including the use of two

very high priority spur gears machined to maximum aircraft quality specs. It is also

evident that the lower bullet portion of the gearcase incorporates IMCO’s unique forward

extended skeg with a built-in low water pick-up inlet.

(Backend of the SCX gearcase machined with two pockets and downshafts for

pinion gears.)

At this time, IMCO has manufactured an initial run of ten complete “Dual Downshaft”

units, several of which are out on loan to specific boaters for field testing. So far all

indications are positive without any reported failures. Some of those units have already

returned to IMCO for tear-down and inspection receiving a clean bill of health.

So now comes the important part. How much is this upgrade going to cost? As listed on

the IMCO website, a “Dual Downshaft” is approximately $4,500 to $5,000 more than a

conventional SCX lower. A little over $2,000 of that price tag is in custom gears alone.

Although it is difficult to calculate at this time how much additional longevity the “Dual

Downshaft” will deliver a boater, it should be considerable, especially if you’re talking

about boats with horsepower approaching 1,000 or maybe more. When you compute

the cost of Bravo drive rebuilds every 30 or 40 hours, the “Dual Downshaft” begins to

look like a bargain and an insurance policy against inconvenient down-time during

optimum boating season for repairs.

(Comparison – SCX Dual Downshaft gearcase (right), SC gearcase on left.

Note the forward extended fin/skeg on the SCX Dual Downshaft case.)

(Comparison – SCX Dual Downshaft gearcase (left) opposite SC lower unit on right.)

If you’re looking to place an order, the much larger production run of “Dual Downshafts”

is projected to be available after the first of the year (mid-January to early February

2019).

The IMCO “Dual Downshaft” is not a replacement or substitute for a Mercury Racing

number Six or an M8 drive, but it might be the “missing link” that high performance

boaters have been wishing for.

For more information: contact IMCO Marine, 909-592-6162 or check it out online at

www.imcomarine.com, 510 E. Arrow Highway, San Dimas, CA 91773

(SCX Dual Downshaft with exposed spur gears.)

(SCX Dual Downshaft complete assembly.)

Written by : Bob Brown

Photos : Bob Brown / Imco Marine

Ask any marine repair shop involved in routinely servicing high performance boats,

engines and propulsion systems….“what’s the single most abused and broken

component encountered on a regular basis?” That’s easy, the standard Mercury Bravo

One sterndrive.

When Mercury introduced the Bravo One back in 1988 (replacing the TRS drive), it was

mated to a 330 horsepower 7.4L (454 c.i.) GM V-8 block. For some boaters, the stock

engine package didn’t pack enough punch, and the quest for more horsepower and

torque was on, and it hasn’t stopped.

To Mercury’s credit, they’ve made attempts over the past 30 years to introduce better,

stronger, more durable versions of the Bravo by developing the XR and XZ models.

Improved and beefier internal components like upgraded straight-cut gears, shafts and

bearings helped the XR and XZ drives, but it was never enough to keep pace with the

hot rod water crowd who ignore factory recommended Bravo max horsepower and

torque limits. According to IMCO, the majority of Bravo style drive failures occur at

about 3,500 to 4,000 rpm when engines are delivering their maximum torque output or

during hammer-down acceleration.

(Top view of SCX gearcase with machined holes for downshafts.)

So, the mechanical carnage caused by excessive power has become an accepted fact

of high performance Bravo boating. Those who tried to beat the system either turned to

aftermarket companies building hybrid Bravo type drives on steroids or took the leap to

Mercury Racing number Six or M8 drives causing a significant dent in their wallet.

Unbeknownst to most everyone in the performance marine industry, IMCO Marine,

already well known for its SC, SCX and SCX4 drive options, has been developing

something brand new over the past 18 months, targeted to bridge that gap in the Bravo

market between 600 to 1000 (possibly more) horsepower. Some might call it the

“missing link.” It’s the new IMCO SCX “Dual Downshaft.”

(Dual custom precision ground, not cut, spur gears.

Before getting into the details of the new drive, proper appreciation of the development

and engineering process that went into this project is in order. First, it was developed

and engineered in-house using CAD software. But it didn’t stop there. A little over a year

ago, IMCO invested a considerable sum of money in a high-end 3D printer. As the

engineering unfolded, what was on the computer monitor was ‘printed-out’ as full-size

actual parts in plastic before any of the machining or mold making began. So much for

wasteful trial and error.

(In-house IMCO 3D printer)

So here’s the concept behind the “Dual Downshaft”. As more boaters cram more

horsepower into the engine compartment, conventional single vertical downshaft Bravos

kill the relatively small lower unit gears. Serial abusers find a way to repeatedly tear-up

new gear sets in duty-cycles of less than 30 or 40 hours, and sometimes even less.

With only one standard downshaft and single gear to gear contact mandated by the tight

confines of the Bravo gearcase however, installing bigger, more heavy-duty gears are

not a feasible solution as long as the stock Bravo lower unit wants to maintain its slim

and efficient external profile.

(SCX 1-1/4” propshaft with two sets of gears ready for dual downshafts.)

Recognizing the durability superiority of Mercury Racing’s number Six and M8 drives,

also with dual downshafts allowing massive torque loads to be spread thus resulting in

less gear wear and fatigue, creating a Bravo style lower with twin downshafts was

IMCO’s answer to achieve greater strength, more reliability and longer duty-cycles with

higher output engines.

Here are some things to remember however. First, the new IMCO “Dual Downshaft” is

only compatible with an IMCO SCX upper. Next, it is not intended to be applied as a

‘surfacing’ drive like the SCX4. For that reason, the “Dual Downshaft” is intended

primarily for use on single engine air entrapment/cat hulls (especially deckboats) with

massive horsepower or vee-bottoms with big output twin or single powerplant

applications. The “Dual Downshaft” is two-inches shorter than a stock Bravo and retains

an internal shifting cone-clutch (no external transmission needed) and utilizes

conventional wet sump lubrication. The propshaft is 1-1/4-inch, however a 1-7/16-inch

propshaft option may be offered in the future. All IMCO SCX gear ratios are available.

Internally, IMCO has integrated a number of ingenious solutions including the use of two

very high priority spur gears machined to maximum aircraft quality specs. It is also

evident that the lower bullet portion of the gearcase incorporates IMCO’s unique forward

extended skeg with a built-in low water pick-up inlet.

(Backend of the SCX gearcase machined with two pockets and downshafts for

pinion gears.)

At this time, IMCO has manufactured an initial run of ten complete “Dual Downshaft”

units, several of which are out on loan to specific boaters for field testing. So far all

indications are positive without any reported failures. Some of those units have already

returned to IMCO for tear-down and inspection receiving a clean bill of health.

So now comes the important part. How much is this upgrade going to cost? As listed on

the IMCO website, a “Dual Downshaft” is approximately $4,500 to $5,000 more than a

conventional SCX lower. A little over $2,000 of that price tag is in custom gears alone.

Although it is difficult to calculate at this time how much additional longevity the “Dual

Downshaft” will deliver a boater, it should be considerable, especially if you’re talking

about boats with horsepower approaching 1,000 or maybe more. When you compute

the cost of Bravo drive rebuilds every 30 or 40 hours, the “Dual Downshaft” begins to

look like a bargain and an insurance policy against inconvenient down-time during

optimum boating season for repairs.

(Comparison – SCX Dual Downshaft gearcase (right), SC gearcase on left.

Note the forward extended fin/skeg on the SCX Dual Downshaft case.)

(Comparison – SCX Dual Downshaft gearcase (left) opposite SC lower unit on right.)

If you’re looking to place an order, the much larger production run of “Dual Downshafts”

is projected to be available after the first of the year (mid-January to early February

2019).

The IMCO “Dual Downshaft” is not a replacement or substitute for a Mercury Racing

number Six or an M8 drive, but it might be the “missing link” that high performance

boaters have been wishing for.

For more information: contact IMCO Marine, 909-592-6162 or check it out online at

www.imcomarine.com, 510 E. Arrow Highway, San Dimas, CA 91773

(SCX Dual Downshaft with exposed spur gears.)

(SCX Dual Downshaft complete assembly.)

Written by : Bob Brown

Photos : Bob Brown / Imco Marine